Core Technology – DHN

DHN (Digital Holographic Nanoscopy) enables high-speed, label-free 3D profiling at nanometer-level precision using optical interference and digital signal processing.

- One-shot 3D measurement without mechanical scanning

- Robust to vibration – suitable for in-line inspection

- Applicable to transparent materials like glass

- Enables real-time inspection with sub-nanometer resolution

TGV & Glass Substrate Inspection

HICKS DHN systems support advanced inspection for Through-Glass Via (TGV) structures and glass substrates:

- Measurement of CD (Critical Dimensions) from top-waist-bottom

- Defect detection: voids, cracks, copper fill uniformity, misalignment

- Support for wet etching and laser drilling evaluation

- 3D profiling of internal via geometry and defects

Sample Applications

- Smartphone cover glass inspection (dent, scratch, edge crack)

- Transparent films (wrinkles, coating voids, black spots)

- Micro-lens refractive index profiling

- Bio-cell line and axis analysis on transparent substrates

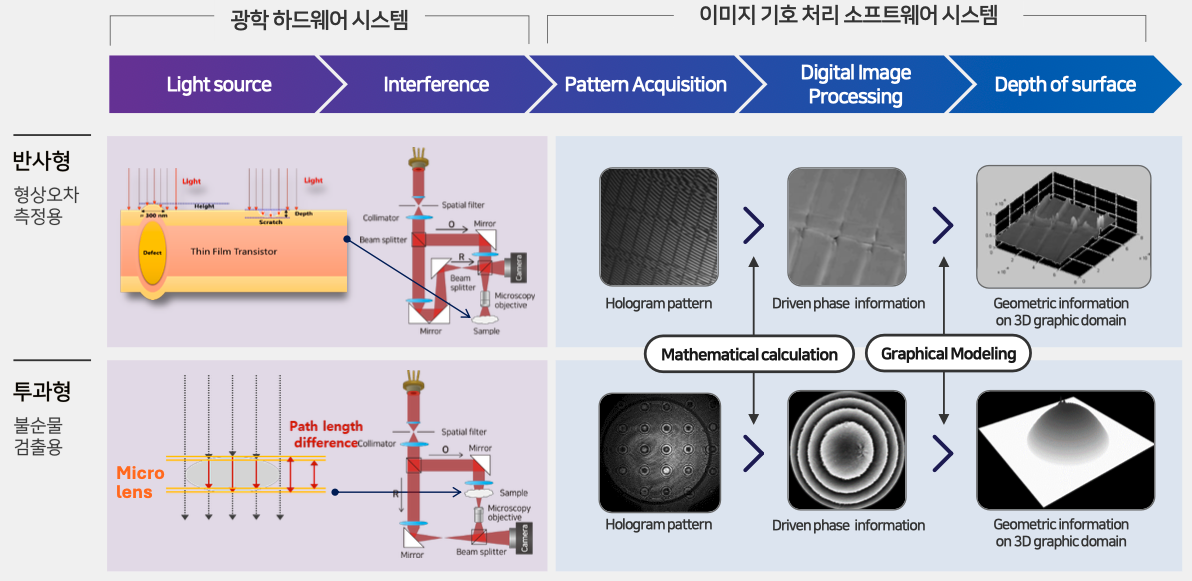

Technology Diagram – DHN Workflow

Light Source → Beam Splitter → Sample & Reference Path → Interference Pattern Acquisition → Digital Image Processing → 3D Surface Depth Output

DHN 기술은 광학 간섭 기반 측정과 후속 디지털 연산을 통해 고속 고정밀 3D 형상 데이터를 생성합니다.

Competitive Advantages

- Faster and more robust than Confocal, AFM, or WSI

- Real 3D measurement without moving parts

- Low sensitivity to vibration and thermal noise

- Supports transparent and reflective inspection targets

Business Impact

By implementing DHN inspection solutions, customers gain:

- Improved yield in TGV and glass interposer fabrication

- Reduced failure rate through early-stage defect detection

- Higher process reliability for advanced packaging and display

- Scalability for mass production with automation readiness